Products

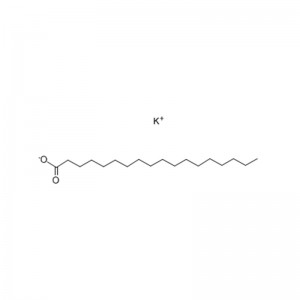

Potassium Stearate

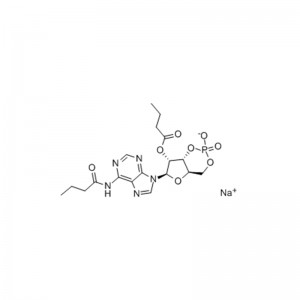

Structural Formula

Physical Properties

Appearance: White to yellow-white waxy solid

Density:1.12 g/cm3

Water solubility:insoluble

Safety Data

Belongs to the dangerous goods

Customs code:2915709000

Export Tax Refund Rate(%):13%

Application

Used as emulsifier, can be used in cakes, the maximum dosage is 0.18g/kg, and also used as surfactant, fiber softener and loosening agent; Foaming agent; Anticoagulant; Stabilizer.

Description of use.

As an anionic surfactant, it is widely used in acrylate rubber soap/sulfur combined vulcanization systems. Anionic surfactants. Often referred to as potassium soap or soft soap, mainly used in cream and shampoo cosmetics, as emulsifiers and detergents. Has a high emulsification efficiency, but is sensitive to hard water, can generate calcium soap with hard water, so that the emulsion is deformed or destroyed, is a calcium-sensitive emulsifier, and therefore should be noted in the cosmetic production process.

Stability: stable at room temperature and pressure, avoid contact with incompatible materials. Reacts with strong oxidizing agents. Soluble in cold water, more soluble in hot water and hot ethanol, used as a softening agent for fibers.

Preparation of potassium stearate

1. The product is obtained by reacting stearic acid with potassium hydroxide at high temperature and then cooling.

10g of stearic acid dissolved in 100mL 95% ethanol, titrated with 0.5mol/L potassium hydroxide alcohol solution, phenolphthalein as indicator, titrated to the equivalent point, the precipitated potassium stearate soap will be filtered out. The crude product can be recrystallized in 95% ethanol to obtain the pure product.

Storage conditions

Sealed storage, stored in a cool, dry warehouse.